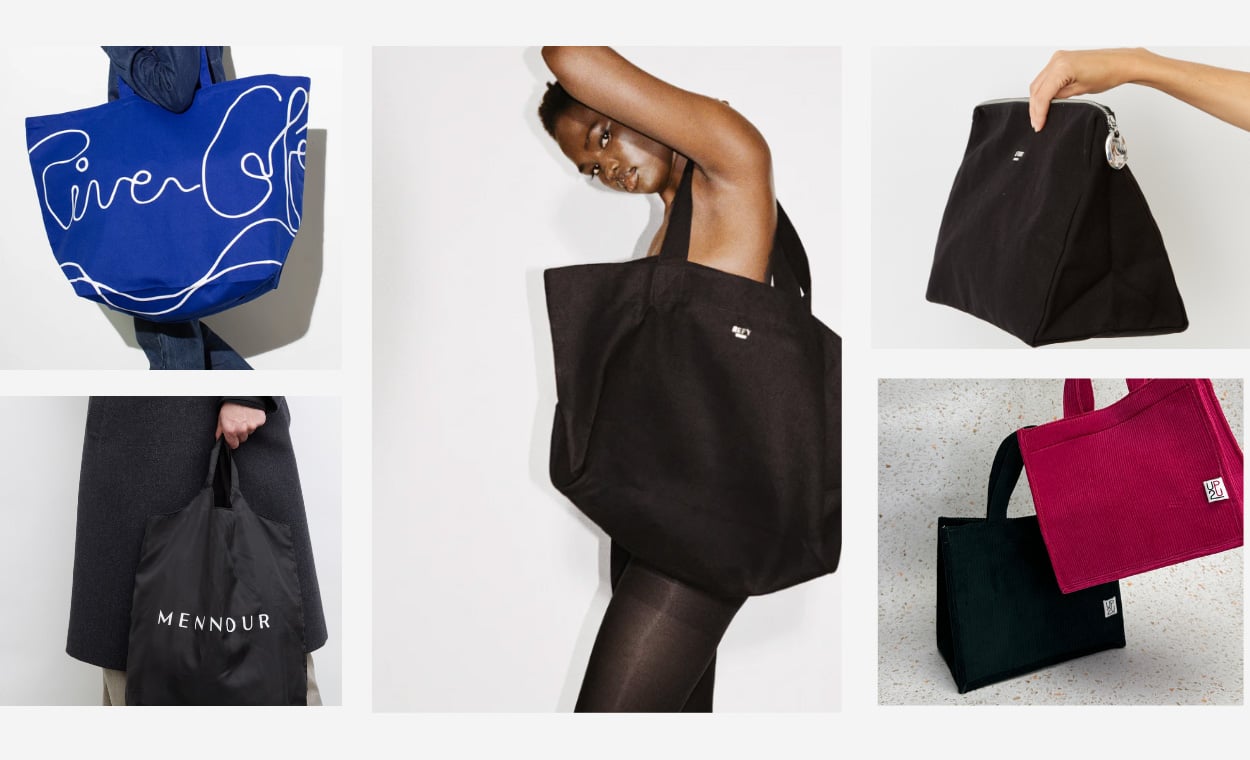

Choosing a fibre from a design perspective can be challenging enough, but the fibre that a fabric is made from has numerous environmental and social impacts. It can be difficult to work out the best option when selecting a fibre.

Introducing Fibre Focus, our fabric blog that breaks down the various impacts of a fibre from an environmental, social justice and design standpoint. It is important to also consider any potential impacts a fibre might have if it were to become more popular.

Design advantages :

- Strong and durable

- Soft, breathable and lightweight

- Excellent drape

- High elasticity

- Antibacterial and anti-odor

- Relatively anti-crease compared to other fibres

Design disadvantages :

- Generally a knitted fabric, and so there can be issues with screen printing

- Lyocell is more expensive than other fibres

Environmental impacts :

- Generally produced in a closed-loop production system. This recycles and reuses water and chemicals and minimises chemical water pollution

- Lyocell is a man-made fibre produced from natural raw materials, usually wood pulp

- Trees are renewable and absorb and sequester CO2 during photosynthesis

- Trees must be felled to obtain the raw material

- Lyocell biodegrades, unlike polyester

- Mechanical equipment is used to spin the pulp into yarn – this results in carbon emissions

- Anti-wrinkle fabrics require less energy during the consumer use phase

- The production process involves amine oxide – which has numerous environmental and social impacts. However in a closed-loop production system amine oxide presence in effluent is minimised

- Trees flourish under organic circumstances

Social impacts :

- Creates jobs, which generate income for households

- Income is dependent on mechanical factories or mills – unlike fibres that can be hand processed such as cotton or silk

- Increased risk of occupational chemical exposure for lyocell producers

- Low washing temperatures and anti-wrinkle properties can save households money during the consumer use phase

Positive potential impacts :

- Cultivating the raw materials (trees) can preserve air, water and soil quality

- Prevention of soil erosion

- Preservation of natural biodiversity and ecological equilibrium

- Increased tree populations

- Decreased CO2 levels and increased oxygen levels

- Lyocell’s durability means that it is a perfect candidate for upcycling

- Decreased dependence on synthetic petrochemicals, and reduced demand for oil drilling

- The eucalyptus tree is the most commonly used material for lyocell. Eucalyptus has many applications and can be used as a natural dye and for cosmetics and medicine

Negative potential impacts :

- Increased risk of occupational chemical exposure for lyocell producers

- Increased risk on amine oxide pollution

- The trees used for pulp must be replaced, else the tree population will decline and the air quality will be impacted

- Job loss for producers in other fibre sectors

So there you have it, a simple breakdown of lyocell’s impacts that you can keep in mind when buying, sourcing or designing.

Fiber Focus: Lyocel