There are several advantages to use a digitally printed fabric to manufacture your textile products.

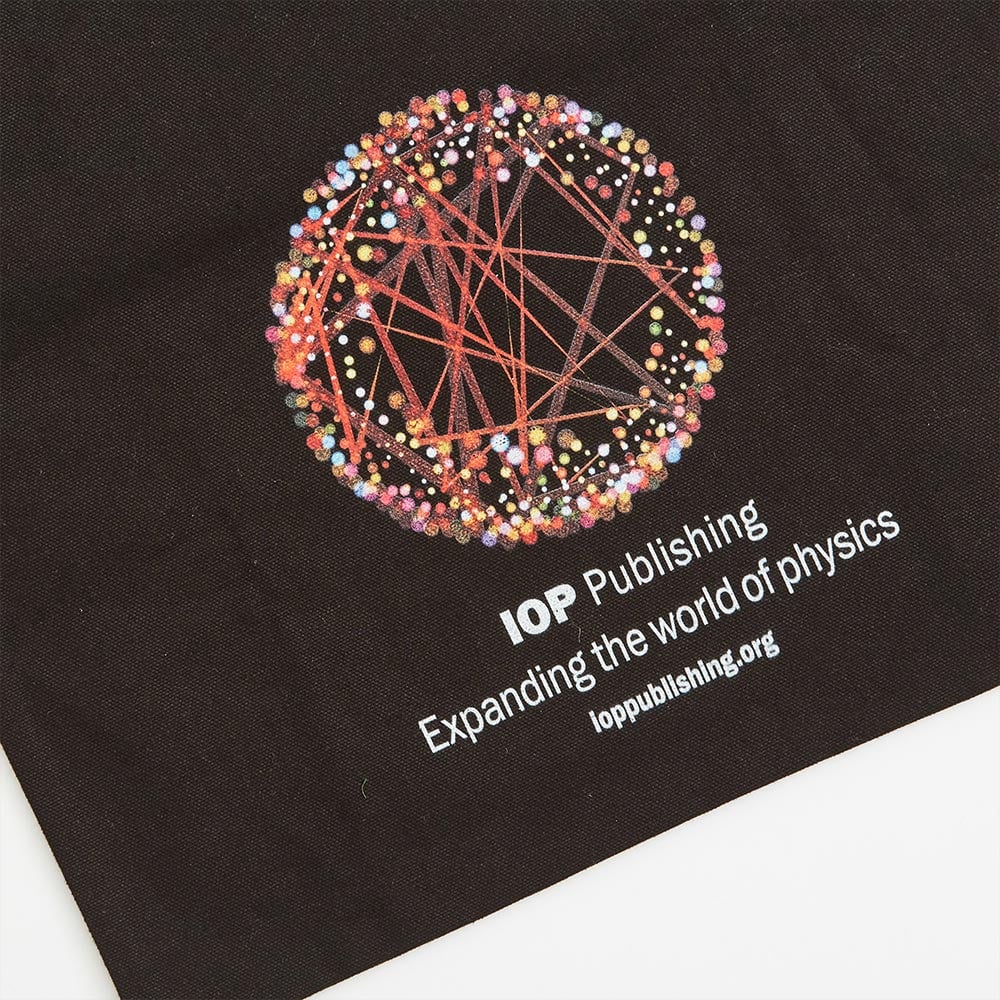

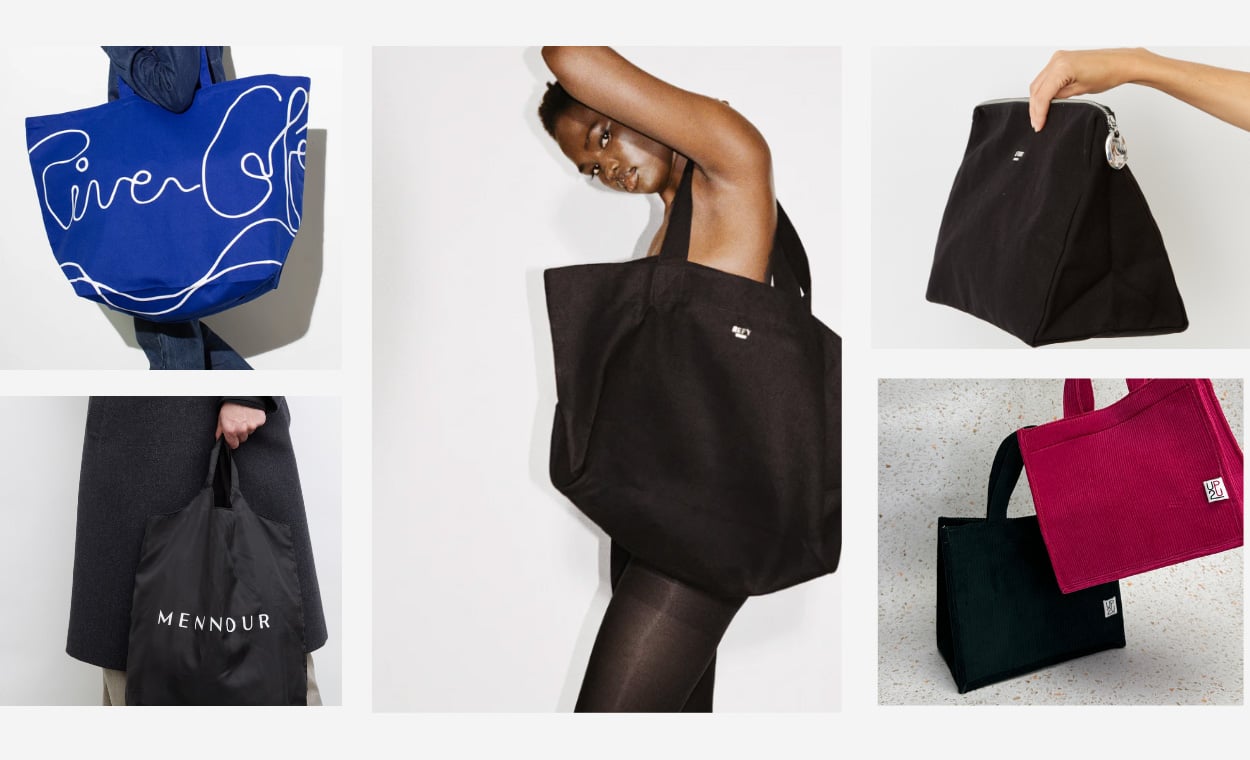

- Digital printing allows for high-quality printing on fabric with vibrant colours and sharp details. It can reproduce intricate designs, photographic images, and even gradients that may not be possible with traditional printing methods.

- Digital printing on a fabric enables customisation, making it easy to create one-of-a-kind designs for a specific event, brand, or product. It’s also possible to print small runs of fabrics, which makes it perfect for personalized gifts, small businesses, or niche markets.

- Digital printing is a quick process, and the turnaround time is typically shorter compared to traditional printing methods. This makes it an excellent option for last-minute projects or tight deadlines.

- Digital printing can be more cost-effective than traditional printing methods for small to medium-sized orders. The process doesn’t require expensive setup fees or printing plates, making it a more affordable option for short runs.

- Digital printing produces less waste compared to traditional printing methods since there’s no need for printing plates or other materials. It’s also possible to use eco-friendly ink and fabrics, making it an environmentally friendly option for printing tote bags.

Can I Print Digitally On Any Type Of Fabric?

It is possible to digitally print on a wide variety of fabric types, but the quality and results may vary based on the fabric’s fibre content, weave, finish, and colour.

Digital printing technology has advanced significantly in recent years, and many fabric types can now be printed using various digital printing techniques, including dye sublimation, direct-to-fabric printing, and pigment printing.

However, some fabrics may require special preparation or pre-treatment before printing to achieve the desired results.

For example, fabrics with a high synthetic content may need to be pre-treated with a bonding agent or heat press to improve ink adhesion and prevent bleeding or fading.

Moreover, certain fabrics may not be suitable for digital printing due to their texture, weight, or colour.

It’s always best to consult with our experts to determine the best fabric type and printing technique for your specific project.

Why Work With Us For Your Digitally Printed Product?

We are an award winning sustainable and ethical manufacturer based in London UK.

Working with us gives you access to:

– Manufacturing facilities based in Pondicherry, South India fully geared up for screen printing, plastisol printing, digital printing, sewing, embossing, embroideries and more.

– The largest manufacturer in the world for eco-packaging, reusable products and sustainable promotional products.

– A trusted supplier able to produce small and large quantities, from 100 units to a million.

– An expertise in manufacturing sustainable and eco-friendly high quality products.

– Flexibility: we produce on order and we will provide an answer to any creative and technical challenge you could bring to us.

– A range of additional services, such as prototyping, packing, labelling, fulfilment and worldwide deliveries.

We can digitally print on:

- Any textile fabric in white or ready-to-dye fabric

- Any textile fabric in black or dyed to pantone

- Any other material like leather, faux leather, PVC, synthetic fabrics

We can produce from 1 – 1 million units using our digital printing machine which uses eco-friendly REACH compliant inks.

What Are The Advantage Of a Digitally Printed Fabric ?